Four Wheel Alignment

Ok, let's get the admissions out of the way before we start; this is a very amateur method of checking all 4 wheels are pointing where they should be.

It's very low tech with no lasers in sight, but it can be reasonably accurate. It all comes down to how much time and care you're willing to take over the job.

If you do have a friendly local garage with modern equipment and, more importantly, someone who knows how to operate it properly and who is prepared to take the time on your quaint little plastic car, then my advice would be - let them do it !

DIY is certainly possible but it typically takes me an hour or more to set up, take readings and then do any adjustments. Invariably if any adjustments are required then it will be another hour on top to settle the suspension and repeat the job, so that's a morning or afternoon gone..... YMMV of course

Still convinced you want to try ? Ok, this is my take on the job.

Checking front and rear wheel alignment

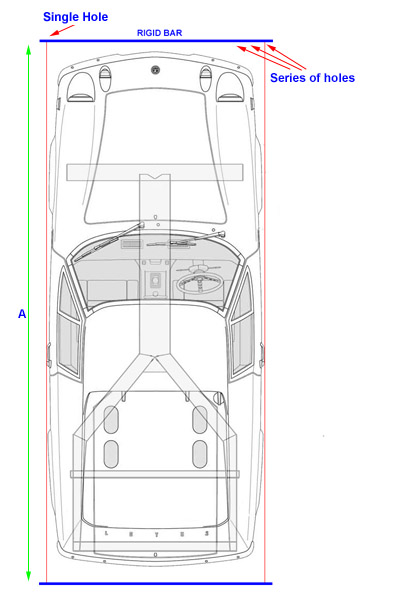

Schematic outline of the measurment rectangle

The first image shows the basic set-up with string down the sides held taught between rigid bars at the front and back, so the basics are simple.

The schematic shows an overview, let's start with the two end bars. I used "T" section aluminium but anything will do providing it's rigid and won't flex.

Clamp both bars together and drill through one into the other, that way at least your starting points will be in line. I drilled a single hole at one side with a series of 3 or 4 holes at the other, this allows the bars to be used with differing width cars.

That's the easy bit over with.

I use 4 axle stands to support the bars at wheel centre height. You need heavy stands or something to weight them because the stress you'll need to keep the string taught is likely to pull one over at some point.

The basic set up is to arrange as in the schematic and to ensure you have a perfect rectangle the only way I could see was to measure the string between bars, dimension "A" in the schematic.

I don't aim to get perfection here as I'm using an extendable rule which obviously flexes, but you should get to within 5mm.

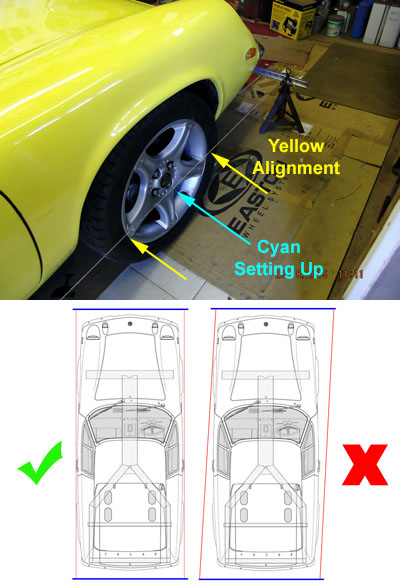

Moving on to the third image, I measure the wheel centres across the axle, shown here in cyan text.

Hopefully you'll get them identical across the axle, and if your front and rear tracks are the same then it should be the same all round the car. On the TC Europa the front and rear tracks are different so my readings differ, but the axle readings are the same.

You're aiming to get both strings parallel to the axis of the car and hopefully centralised, as shown in the sketch below the photograph.

This usually takes me several attempts to get it reasonable, again I don't aim for perfection but this time 1 or 2 mm is achievable and I think this is important.

What you don't want is the strings skewed off axis, I doubt this would matter too much at the front, but at the rear it will make a big difference to any shims you need to change.

Now you're ready to take the actual alignment readings, as shown in yellow text on the photo.

A clipboard with a simple form and a couple of minutes later you're all done. I generally walk round twice, just to check I haven't kicked an axle stand or something on my first visit.

Centering and taking alignment readings

Ideally you should be getting the front reading higher than the rear on all wheels, which indicates the amount of toe-in.

At the front this might not happen, it depends how accurately you have your steering set in the straight-ahead position. If you're slightly off then you could find a massive toe-in on one side with toe-out on the other.

Not to worry, just do the maths to get the correct toe in.

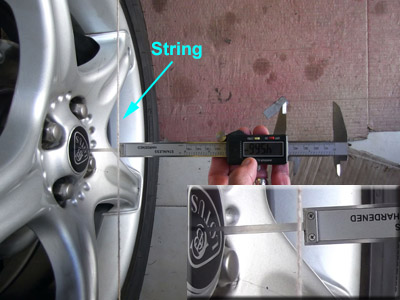

A cheap Digital Vernier simplifies the readings

The last photograph in this series shows the cheap digital vernier I use for measuring. Once upon a time you needed to sell your granny to get one of these tools but nowadays they are under a tenner on Ebay. It's a no-brainer, which some would say also describes the author...

Seriously though, you'll be surprised how accurately you can measure and it's far simpler than holding a steel ruler below the string

Although this is very crude and incredibly time consuming the reason I've persisted with it is because this method does give you the toe measurements for individual wheels in relation to the axis of the car.

Why is that so important ? Well, not so much at the front because you'll naturally sort out any bias with the steering wheel but at the rear the only control you have is the amount of shims placed on either side.

For some reason that I don't understand, on my car I have more shims on one side than the other. No accident damage, genuine parts, it just is like that. TADTS. Lotus, eh ?

So if I did an overall measurement and then divided shims equally between the sides then I'd have one arm with toe-in and the other toe-out. Despite my "what if ?" curiosity I haven't tried that, but I suspect it wouldn't go well.

TADTS - "They All Do That Sir", Lotus Dealer Manual, Chapter 2:Dealing with Customer Complaints