Ok, now bear in mind that I know nothing about suspension design, everything I have is secondhand and a distillation of other's wisdom. But you have to start somewhere, so why not with the original design ?

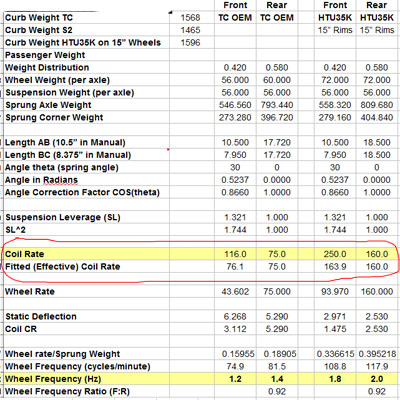

Taking the workshop manual, overall weights and distributions from period road tests, measuring the suspension links/angles and weighing whatever components I could (so that's where my bathroom scales went !) it's possible to put together a basic spreadsheet to calculate the wheel frequencies.

I doubt my sums are absolutely correct but for now I'm just trying to establish the magnitude of any changes in relation to what I've got now rather than calculate the exact wheel frequencies.

So, using the OEM numbers I get wheel frequencies of approx 1.2 front, 1.4 rear, neglecting any contribution from the roll bar. Internet research leads me to think that rates much above 2.0 are increasingly track orientated and as I'm a road driver, this will be my arbitrary maximum.

Traditionally you have a slightly higher frequency at the rear as this is thought to reduce pitching as the car rides a bump at speed, the idea seems to be that the differing rates smooth out the ride. But several articles claimed this was no longer a big deal in modern systems. I don't know who is right but I'm curious.

The second part of the equation, ride height, was equally confusing. Bar room logic says "lower is better" and it's possibly to get the front of the car very low indeed. But at the rear you have the angle and clearance of the driveshafts to consider, which has a secondary, if minor, effect on the rear geometry.

I can't find any simple way to work out the front/rear centre of gravities or roll centers so I opted for a relatively small ride height reduction and see what happened.

For no other reason than "you have to start somewhere" I increased the numbers on the spreadsheet and ended up with 250lbs/ins front springs and 140lbs/ins rear springs. This will give me identical F/R rates of 1.8, which goes against the OEM preference for a imbalance in rates. This is me testing the "it doesn't matter any more" theory about F/R ratios.

If it's wrong, then I'll modify the 140lb springs by removing 2 coils to get 160lb rate, the adjustable platform dampers should allow this. If that turns out better, I'll buy another set in the correct length.

Now 250lbs sounds ridiculous compared with 140 or even 160 rears and well away from the original 116lb/ins standard front springs, but it's not as wild as it sounds.

At the rear the spring is almost vertical and is acting directly on the same plane as the hub carrier bolt (S2 is slightly different) which means the effective spring rate is 140 or 160lbs.

At the front the springs are inclined and the larger the deviation from vertical the lower the effective spring rate. Add in the leverage between the point of application and hub/wheel location (damper and trunnion bolt centres) and that 250lbs drops away.

For my rough calculations, the 250lb spring had an effective rate circa 163lbs due to the geometry, and on the same dimensions and assumptions, the OEM 116lbs drops to 76lbs

Interestingly this puts the OEM F/R rates almost identical whereas my original 140lbs selection didn't. Yep, this is a "doh" moment.

Spreadsheet comparison between OEM and proposed spring rates

So, the new springs and dampers arrived and were assembled. A few gentle rides around the block to settle it in and then begin experimenting with damper rates. Gradually increasing the rates to mid way a couple of things started to become clear as it all settled down.

Firstly the ride height, although it looked "racey" there was quite a bit of rake to the car, it seemed too low at the front compared with the rear. Something was adrift in my calculations, either the assumptions, overall weights or F/R distribution.

Secondly, although normal driving and good roads felt ok I didn't feel entirely happy with the way it handled very bumpy roads; it wasn't leaping towards the ditches but I certainly didn't feel relaxed the way you should do.

So, was this a ride height, roll centre or suspension frequencies problem ? I didn't know and still don't, but I do know how I got away from it.

Firstly I modified the ride heights, lowering the rear and fractionally raising the front. There is still a F/R rake, but not so much. About 6-8mm over the chassis spine between front and rear, but the floorpan measurements indicate a greater rake. I decided to work on the chassis which has the suspension bolted to it rather than the bodywork which is, after all, just there to keep the rain off.

Secondly I reduced the height of the rear springs which effectively increases the rate from 140 to 160lbs/ins. This gives me F/R wheel rates of 1.8/2.0 which now leaves me with a F/R comparison ratio of 0.92. Which, by some strange coincidence, is exactly the ratio on my spreadsheets that Lotus had in 1972.... hmmm.

In combination these gave me more confidence and over the same roads the car was much improved. More than I expected if I'm honest, but I did say I'm learning here and I'm sure with a better driver there would be more to come. But sadly, that's above my skill set.

If you'd like to see the format I used to record the changes, click here

If you'd like to see the current readings, click here. Note - there's a very "non-engineering" mixture between Imperial and Metric measurements.